Ntse-point screws zoo ib yam li tshuab screws, tab sis cov xov ntawm cov ntsia hlau yog cov xov tshwj xeeb rau tus kheej tapping screws.Nws yog siv los khi ob lub hlau nyias ua ke los ua ib qho, thiab qhov me me yuav tsum tau ua ua ntej hauv cov khoom.Vim lub siab hardness ntawm cov ntsia hlau no, nws tuaj yeem ntsia tau ncaj qha mus rau hauv lub qhov ntawm cov khoom siv, tsim cov lus teb hauv xov hauv cov khoom.Hom kev sib txuas no kuj yog ib qho kev sib txuas uas tshem tau.

Thawj feem ntawm cov txheej txheem npaj, lossis cov txheej txheem tsim khoom, rau cov ntsia hlau loj-tailed yog cov txheej txheem coiling.Cov txheej txheem yog thawj coils yuav los ntawm cov khoom siv raw khoom.Cov yam ntxwv tseem ceeb ntawm lub kauj muaj xws li: A, hom B, lub npe C, specification D, khoom E, rauv tooj lossis batch tooj F, kom muaj nuj nqis lossis qhov hnyav.Cov tshuaj lom neeg muaj pes tsawg leeg ntawm carbon steel coils yog: C, Mn, P, S, Si, Cu, Al, uas cov ntsiab lus qis ntawm Cu, Al, zoo dua.

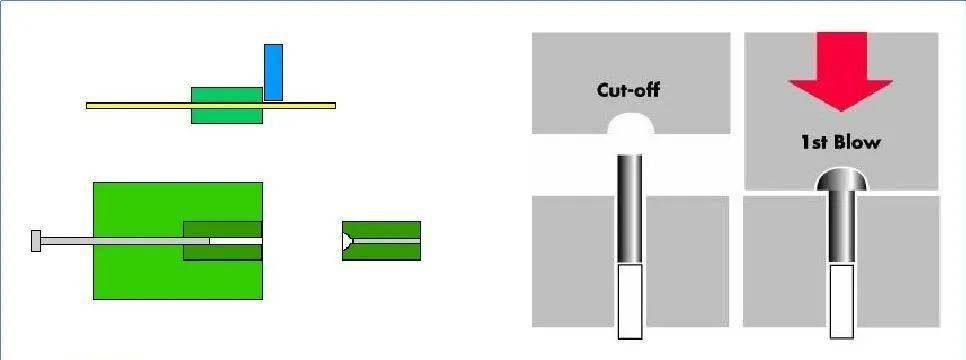

Cov txheej txheem thib ob hauv kev tsim cov screws yog cov txheej txheem kos duab hlau.Lub hom phiaj ntawm cov txheej txheem kos duab yog ua kom tiav cov kab uas peb xav tau (piv txwv li mus txog 3.5 hli hlau kos duab).

Cov txheej txheem thib peb yog cov txheej txheem txias taub hau (heading).Los ntawm kev sib cuam tshuam ntawm cov tuag kom zoo, ua ntej txiav cov hlau, chim siab rau hauv cov ntsia hlau blanks, tsim lub taub hau, hla zawj (los yog lwm lub taub hau hom) xov dawb kab uas hla thiab pas nrig ntev, rounding nyob rau hauv lub taub hau, thiab lwm yam.

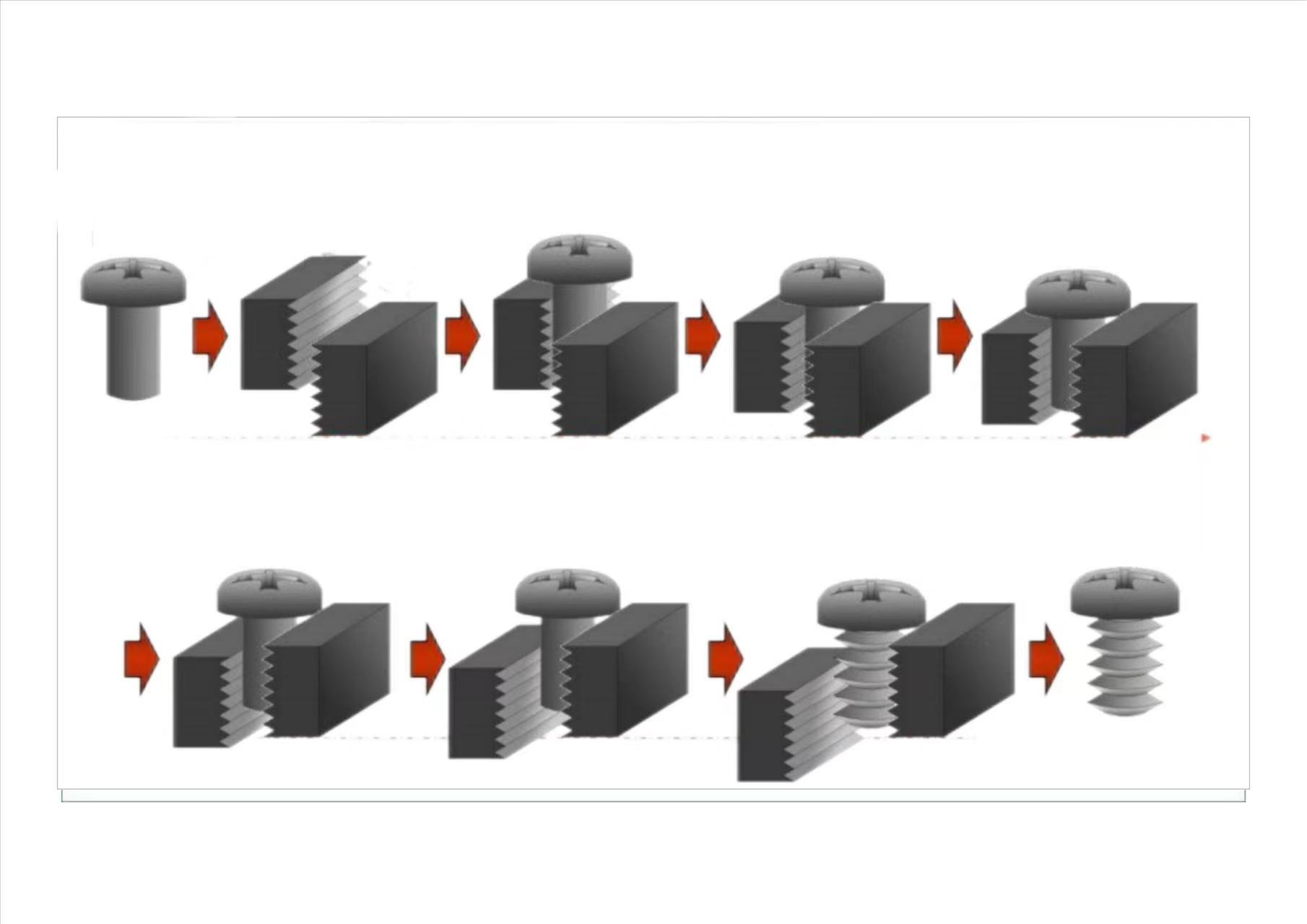

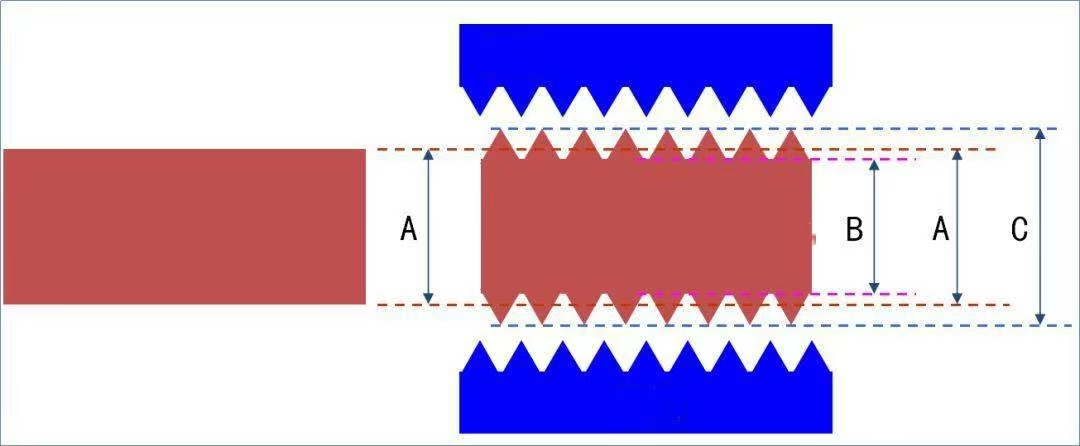

Cov txheej txheem xov dov yog txheej txheem plaub ntawm kev tsim khoom.Cov threads yog dov tawm los ntawm lub taub hau txias blanks, thiab cov qauv xov yog tsim los ntawm kev sib cuam tshuam ntawm cov movable thiab tsau cov hniav.

5 、 Kev kho cua sov txheej txheem

01. Lub Hom Phiaj:

Ua kom cov ntsia hlau nyob rau hauv cov txheej txheem txias taub hau kom tau siab dua hardness thiab lub zog

02. Lub luag haujlwm:

Yuav kom ua tiav nws tus kheej tapping xauv ntawm cov hlau

Txhim kho cov khoom siv ntawm cov khoom hlau, xws li torsion, tensile, hnav tsis kam

03. Kev faib tawm:

A. Annealing: (700 ℃ x 4hr): elongated lub koom haum - orthogonal polygonization.

B. Carburizing tshav kub kev kho mob (ntxiv cov pa roj carbon rau hlau qhov chaw los txhim kho lawv nto hardness, rau hlau cov ntaub ntawv uas tsis muaj carbon ntsiab lus)

C. Tempering kev kho cua sov (tsis muaj cov ntsiab lus ntxiv rau cov hlau, cov qauv sab hauv ntawm cov hlau yog hloov los ntawm kev hloov ntawm qhov kub thiab txias kom tau txais cov khoom siv zoo dua qub) Rau cov lag luam Australian, peb muaj kev ntseeg siab, zoo heev txawv teb chaws cov neeg muag khoom, ntau yam ntawm cov khoom, raws li lub Hoobkas, kev tswj nruj ntawm cov khoom xa tuaj thiab kev ua haujlwm zoo, pab pawg tacit, thiab lwm yam, cov no yog vim li cas peb sib tw rau Australian ua lag luam chips.

Cov txheej txheem kawg yog txheej txheem kho saum npoo, los yog plating.Tom qab plating, qhov saum npoo ntawm cov khoom tuaj yeem pom cov nyhuv xim uas xav tau thiab cov nyhuv anti-oxidation plating.

XINRUIFENG Fastener cov khoom tseem ceeb yog cov ntse-point screws thiab laum-point screws.

Cov ntsia hlau ntse ntse suav nrog cov phab ntsa ntub dej, chipboard screws, tus kheej tapping screws, hom csk taub hau, hex taub hau, truss taub hau, lauj kaub taub hau, thiab lauj kaub framing taub hau ntse-point screws.

Lub laum-taw tes ntsia hlau suav nrog cov phab ntsa ntub dej laum taw tes, csk taub hau nws tus kheej drilling screws, hex taub hau nws tus kheej drilling screws, hex taub hau nrog tus kheej drilling screws nrog EPDM;PVC;los yog roj hmab ntxhua khaub ncaws, truss taub hau nws tus kheej drilling screws, lauj kaub taub hau nws tus kheej drilling screws thiab yias framing nws tus kheej drilling screws.

Kev ua tau zoo heev, tus nqi sib tw, thiab kev xa khoom raws sij hawm yog peb tus ncej ntawm peb txoj kev vam meej.Thiab Peb xav tsim kom muaj kev sib koom tes ntev thiab ncav cuag qhov yeej-yeej nrog txhua tus neeg siv khoom.

Post lub sij hawm: Jun-28-2023